There is so many strapping options available these days, the choice can be difficult. Allow us to help you out with what strapping might be most suitable for you.

What strapping you use will depend on multiple things:

- Size of the goods

- weight of the goods

- Amount of packages sent per hour or per day.

- Loading / unloading method.

- How fragile the goods are and their surface.

- How long the goods are in transport for.

I’m strapping cartons for lifting by hand.

Lets start with and easy one first. If you’re strapping or bundling cartons together or small items for carrying by hand. you should use Polypropylene strapping. With breaking strains of upto 140kg, its more than enough to secure any goods for lifting by hand. Hand PP strapping can be applied by hand with a buckle. But higher volume users should consider some sort of strapping machine, Polyproperline strapping machines such as the semi auto strapping machine only require a small investment and we believe they’re a must have for any distribution warehouse.

I’m Strapping a small number of pallets upto 800kg.

For most general warehouse applications of smaller volume users, consider using heavy duty polypropylene strapping with a breaking strain of up to 400kg and low setup cost, heavy duty polypropylene strapping is the entry level strapping for strapping palletised goods and lighter packs of timber. HD PP strapping can be applied by 3 methods, with a tensioner and buckle. with a tensioner, sealer and sealer or with a single battery powered strapping tensioner Battery powered tools start with an investment of about $3000.00. but they an defiantly be with it if you’re strapping a lot of packages.

I’m doing a high number of timber packages per day.

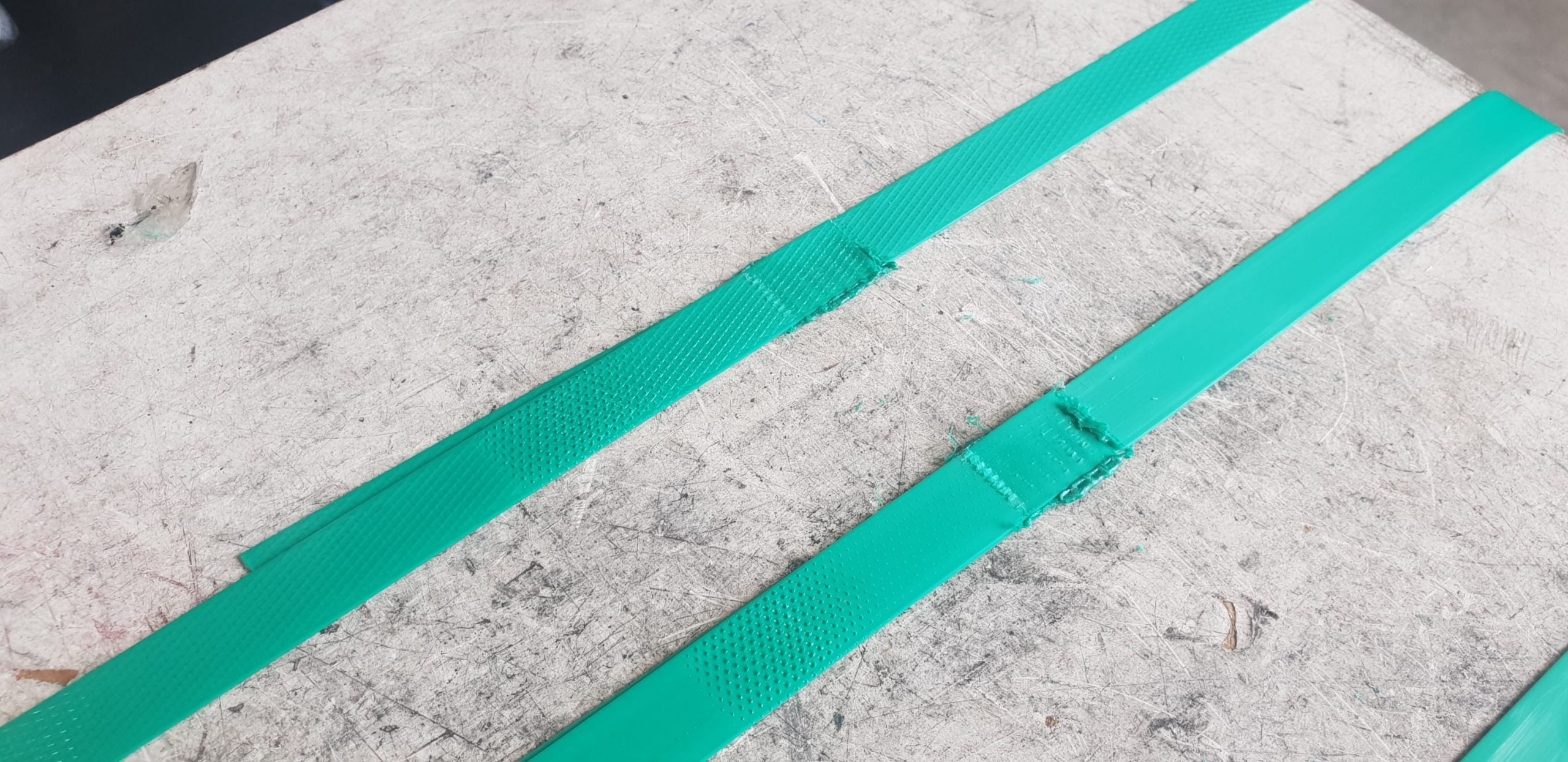

For any user doing timber packaging we recommend the use of, PET STRAPPING, PET strapping has the best bang for your buck in terms of strength, no other strapping besides polypropylene strapping comes close. but PET strapping is capable of higher strengths and is less brittle. it also has a high elongation and medium yield point when compared to steel strapping so its capable of dealing with shock much better, such as tip loading timber.

PET strapping can be applied with a manual tensioner and sealer combo for smaller users. but also with a battery powered strapping tool. A battery powered PET strapping tool is the quickest way to strap palletised goods, short of a fully auto machine anyway. Smaller users going with the manual tools always have the option to goto a battery powered tool later, there’s no need to change strap or dispenser.

I’m doing heavy truck and car parts.

You can consider PET strapping as stated above. if you’re doing a higher amount, but smaller volume users typically use composite strapping. Composite strapping is extremely tough, hard to break and the buckle heaps absorb any shock. the buckle is somewhat slower to apply so we don’t recommend high volume users composite strapping. the composite strapping is also very soft so users can apply it directly to goods and not worry about it scratching. be careful though, on softer goods such as timber if tensioned too tight the composite could still dig into the timber, a use of a corner or strap guard is recommended.

I’m doing small bundles of engineering bar.

You will need to use steel strapping, pusher steel strapping tools are one of the only ways to tension small, round or irregular sized packs and steel strapping is the goto choice on these packages, steel strapping has a small elongation and high yield point. its excellent at strapping small bundles tightly and keeping them tight. smaller volume users you can apply with a ZR tensioner but higher volume users should consider a pneumatic strapping tool.

We hope this blog was helpful to you, but do call us and we can recommend a strapping suitable for your application.

Recent Comments