Pallet wrapping plays a crucial role in ensuring the safe and secure transportation of goods.

Selecting the appropriate pallet wrapping material is essential to protect products, reduce damage during transit, and optimise packaging operations.

To give you a hand in finding the right packaging materials, we’ve put together some information about the different types of pallet wrapping materials available and how to make sure that you’re choosing the right material for your specific packaging needs.

Types of Pallet Wrapping Materials

There are several different types of pallet wrapping materials you need to be aware of, including:

Stretch Films

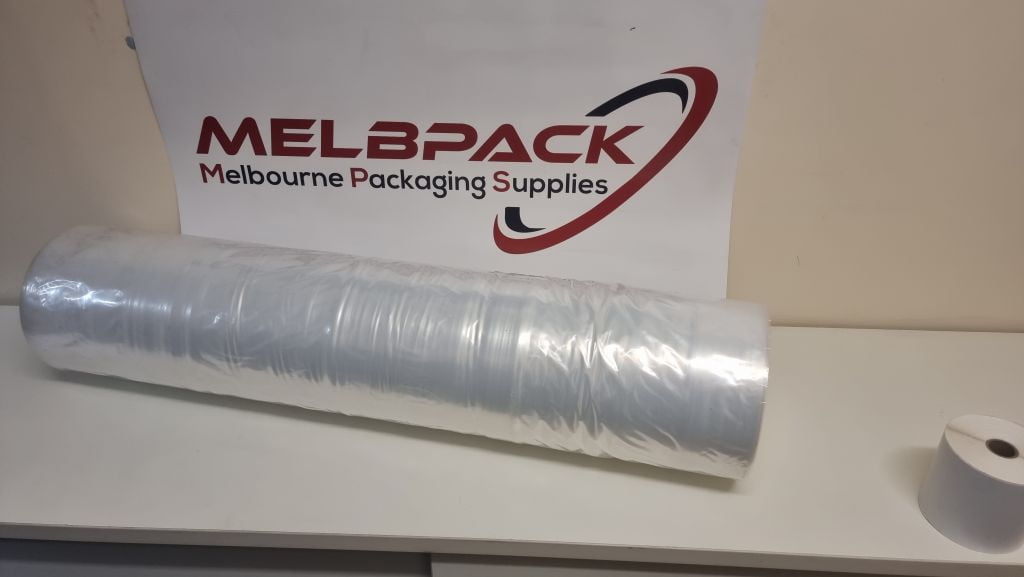

Stretch films are widely used for pallet wrapping due to their versatility and cost-effectiveness.

These films have excellent elasticity and strength, allowing them to stretch and cling tightly to the products and pallets, keeping them bundled together and stable.

Key benefits of stretch films include:

- Enhanced load stability: The stretching ability of the film provides excellent load containment, minimising the risk of shifting or toppling during transportation.

- Protection against dust and moisture: Stretch films create a protective barrier around the pallet, safeguarding the goods from external elements.

- Suitable for various industries: Stretch films are suitable for a wide range of products, including boxes, cartons, and irregularly shaped items.

Shrink Films

Shrink films are another popular choice for pallet wrapping, particularly for products that require a tight and secure packaging solution. Shrink films are applied loosely around the load and then shrink tightly when subjected to heat.

Benefits of shrink films include:

- Conformity to product shape: Shrink films provide a custom fit around the load, ensuring maximum stability and protection.

- Tamper-evident packaging: Shrink films create a sealed packaging layer that is difficult to tamper with, enhancing product security.

- Ideal for heavy or irregular loads: Shrink films offer exceptional strength and durability, making them suitable for heavy or irregularly shaped items.

Strapping

Strapping, such as polyester or steel bands, is an alternative pallet wrapping material that provides robust load containment and reinforcement.

Key advantages of strapping include:

- Superior load stability: Strapping tightly secures the load, preventing shifting or loosening of the products during transportation.

- Excellent load security: Strapping offers a high level of resistance against tampering and pilferage, ensuring the integrity of the packaged goods.

- Suitable for heavy loads or irregular shapes: Strapping is particularly beneficial for pallets with heavy items or unconventional shapes that may require additional reinforcement.

Factors to Consider When Choosing Pallet Wrapping Materials

There are a few things you need to think about when selecting pallet wrapping material for your packaging needs. Here’s some of the key factors to consider:

Load Stability and Protection

Assess the level of stability required for your products during transit. If you have fragile or delicate items, prioritise materials that offer superior cushioning and protection against impact. Additionally, consider the environmental factors your goods may be exposed to, such as moisture or dust, and choose a material that provides adequate protection.

Product Characteristics

Consider the size, weight, and shape of the products being wrapped. Different materials have varying levels of flexibility and strength, so choose a material that can accommodate the specific characteristics of your goods. Fragile items, for instance, may require a more secure and cushioning material, while heavy or irregularly shaped items may benefit from the additional strength and flexibility of strapping.

Cost and Efficiency

Evaluate the cost-effectiveness of the pallet wrapping material, taking into account factors such as material usage, waste reduction strategies, and labour requirements. While some materials may have a higher upfront cost, they are just one piece of the puzzle and could actually result in long-term savings through increased efficiency or reduced product damage.

Environmental Impact

In today’s sustainability-conscious world, consider the environmental impact of the pallet wrapping material. Look for eco-friendly options, such as biodegradable or recyclable films, that align with your company’s sustainability goals and values. Here at Melbourne Packaging Supplies, we work hard to find eco-friendly options and can help guide you in finding the right materials for you.

Wrapping it up

Selecting the appropriate pallet wrapping material is essential for ensuring the safety, stability, and protection of goods during transportation. If you consider the above information you can ensure that your packaging operations are the best they can be.

Evaluate your unique packaging needs and consult with packaging professionals like us, to find the most suitable pallet wrapping material for your business.

We offer a huge range of pallet wrapping materials, as well as the machinery at Melbourne Packaging Supplies and we’re able to help people Australia-wide.

Get in touch with us today for your pallet wrapping needs.

Recent Comments