In the logistics and supply chain industry, securing goods effectively for transport and storage is a critical concern. This is where steel strapping can play a vital role.

Known for its strength and durability, steel strapping is a preferred choice for businesses needing to safely secure heavy and bulky loads. Its reliability in keeping goods intact during transit and storage is unmatched, making it an essential tool in the packaging process.

In this article, we’re going to take an in-depth look at steel strapping and talk about the key benefits of using steel strapping.

Whether you’re new to the world of logistics or seeking to optimise your current packaging processes, understanding the fundamentals of steel strapping is crucial for ensuring your products are transported securely and efficiently.

The Basics of Steel Strapping

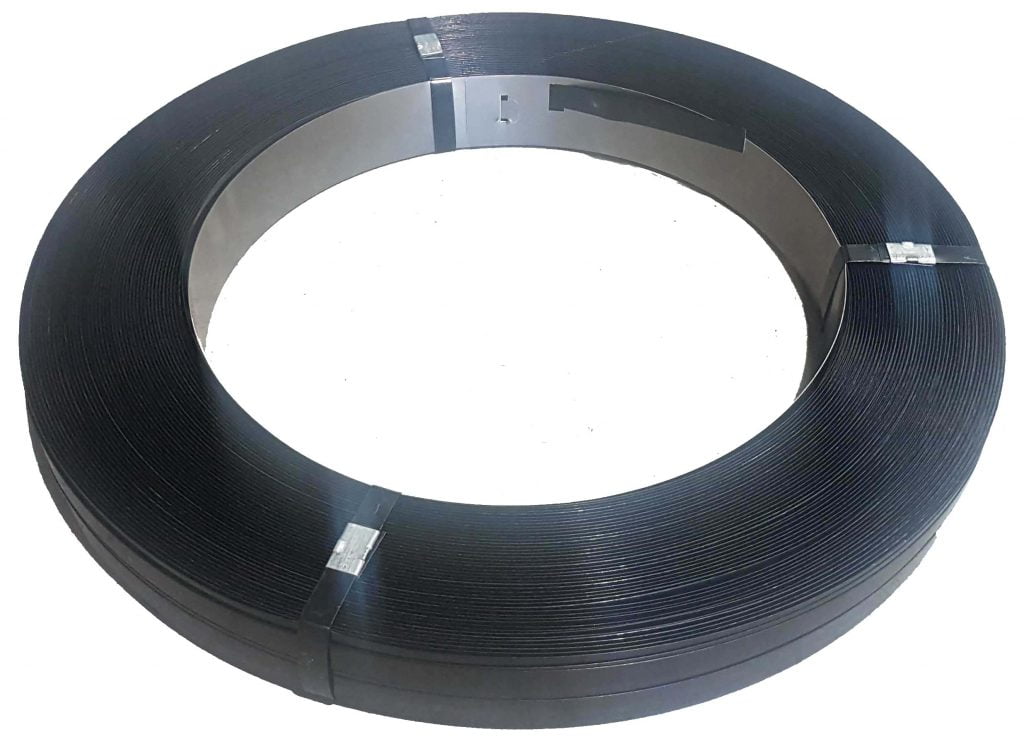

Steel strapping is a type of strapping material made from steel, used primarily for bundling and securing heavy or large items during transport and storage. It is recognised for its high tensile strength and minimal stretch, making it ideal for stabilising loads that are too heavy or too rigid for other materials like plastic strapping.

Steel strapping is commonly used for securing items on pallets, reinforcing wooden crates, and bundling together construction materials or heavy industrial products. Its ability to hold substantial weight and maintain its form under pressure ensures that goods remain stable and undamaged throughout their journey.

There are various types and grades of steel strapping, each suited for specific needs and applications:

- Regular Duty Steel Strapping: This is the most common type, offering a good balance of strength and flexibility. It’s typically used for palletising and bundling medium-weight products.

- High Tensile Steel Strapping: Designed for heavier loads, high tensile strapping has greater strength and shock resistance. It is often used in industries where the goods are subjected to rough handling or long-distance transportation, such as in metal or construction material logistics.

- Heat treated Steel strapping: Heat treated steel is for the heaviest loads, with maximum tensile strength and shock resistance produced by the heat treatment process is the go-to strapping for steel and hardwoods.

- Stainless Steel Strapping: Best suited for outdoor use or in corrosive environments, stainless steel strapping resists rust and degradation. This type is ideal for securing loads in marine or chemical exposure conditions.

- Galvanized Steel Strapping: This type features a protective coating of zinc to resist rust and corrosion, making it suitable for outdoor storage and transport in varying weather conditions.

Each grade and type of steel strapping comes with its specific characteristics regarding break strength, elongation, and corrosion resistance. Choosing the right one depends on factors like the weight of the load, the conditions of transport and storage, and the level of durability required.

What are the Advantages of Steel Strapping?

Steel strapping is particularly useful when transporting or storing more challenging loads, but there are many advantages of this type of strapping, including:

High Strength and Durability: The primary advantage of steel strapping is its exceptional strength. It is capable of holding together even the heaviest and most cumbersome loads without breaking. This makes it ideal for securing heavy or sharp-edged items like metal parts, industrial equipment, and construction materials. Its durability ensures that the strapping maintains its integrity, preventing loads from shifting or becoming unsecured during transit.

Resistance to Environmental Factors: Steel strapping stands out for its ability to withstand various environmental factors. It is particularly suitable for long-distance transportation and outdoor storage because it can endure extreme temperatures, humidity, and exposure to different weather conditions without losing its strength or elasticity. This resilience makes steel strapping a reliable choice for goods that are transported over long distances, including international shipping routes, or stored outdoors for extended periods.

Security: Another significant benefit of steel strapping is the level of security it provides. Its robust nature makes it difficult to cut or tamper with, which is crucial for preventing theft or tampering during transit. For shipments that are particularly valuable or at risk of being tampered with, steel strapping offers an added layer of security that can deter potential theft and ensure that goods arrive at their destination safely and intact.

Common Ways Steel Strapping is Used in Logistics and Packaging

Steel strapping is indispensable in various logistics scenarios, particularly where the safety and security of heavy or valuable goods are paramount. Here are some key application areas and industry examples:

Heavy Machinery and Equipment

In the logistics of heavy machinery – such as industrial tools, large machines, and automotive parts – steel strapping is often the go-to choice. Its strength ensures that these heavy items remain securely fastened to pallets or within crates during transport, minimising the risk of movement or damage.

Construction Materials

The construction industry relies heavily on steel strapping for bundling and transporting materials like bricks, metal beams, and large stone slabs. Steel strapping’s resistance to breakage and ability to handle sharp edges make it ideal for securing these kinds of loads, which are often exposed to rough handling and outdoor conditions.

Metal Industry

In the metal industry, where products like steel coils, rods, and sheets are transported, the strength of steel strapping is crucial for holding these heavy and sometimes sharp-edged materials securely in place. The risk of load shifting or product damage is significantly reduced with the use of steel strapping.

Chemical and Marine Shipments

For transporting barrels, drums, or containers of chemicals, especially in marine environments, steel strapping provides the necessary strength and resistance to harsh conditions. Its ability to withstand corrosion and extreme weather is vital in these scenarios.

Safety and Steel Strapping

While steel strapping is essential for securing heavy loads, proper handling and adherence to safety protocols are crucial to prevent workplace injuries. Here are some best practices and safety measures:

When applying steel strapping:

- Correct Sizing and Tensioning: Always use the appropriate size and thickness of steel strapping for your load. Apply enough tension to secure the load firmly, but avoid over-tensioning which can cause the strapping to snap or damage the goods.

- Use of Tools: Utilise the right tools for tensioning, sealing, and cutting the steel strapping. Tools like tensioners, sealers, and cutters are designed to make the process more efficient and reduce the risk of accidents.

- Regular Tool Maintenance: Keep strapping tools in good working order. Regular maintenance and checks ensure that they function correctly and safely.

- Proper Training: Operators should be properly trained in the use of steel strapping and tools. Understanding the correct techniques and procedures reduces the risk of mishaps.

Safety measures to take:

- Personal Protective Equipment (PPE): Workers should wear appropriate PPE such as gloves, safety glasses, and steel-toed boots when handling steel strapping to protect against cuts and other injuries.

- Awareness of Surroundings: Be aware of your surroundings when applying or removing steel strapping. Ensuring that the area is clear of unnecessary personnel and obstacles can prevent accidents.

- Safe Cutting Practices: When cutting steel strapping, ensure the cut end is controlled to prevent it from whipping back and causing injury. Specialized cutting tools can help in safely managing this.

- Proper Disposal: Dispose of used or excess strapping material properly to prevent tripping hazards or injury from sharp edges.

Steel Strapping Tools and Accessories

For effective and safe use of steel strapping, the right tools and accessories are essential. They not only make the strapping process more efficient but also contribute to the overall safety of the operation. Here’s an overview of the key tools needed:

Tensioners

Tensioners are used to tighten the steel strapping around the load. They ensure that the strap is adequately tight, providing the necessary hold without damaging the goods. There are various types of tensioners available, including manual, pneumatic, and battery-operated models. The choice of tensioner often depends on the volume of strapping required and the physical demands of the task.

Sealers

After the strapping is tensioned around the load, sealers are used to apply a seal or clip to keep the strap in place. Sealers come in different designs – some are separate handheld tools, while others are integrated into combination tools that can both tension and seal. The type of sealer used will usually match the type of tensioner and the specific type of steel strapping.

Cutters

Cutters are used to trim the strapping to the desired length and to remove strapping from packages. Since steel strapping is very tough, these cutters are specially designed to handle the material’s strength and thickness. Safety is a key consideration when choosing cutters, as the cutting process can be one of the more hazardous aspects of strapping.

Dispensers

Dispensers hold rolls of strapping and typically feature a braking system to control the release of the strap. They are essential for managing large coils of strapping material, preventing tangling, and making the material more accessible and easier to handle.

When it comes to choosing the right tools, the choice depends on factors such as the volume of items being strapped, the size and weight of the packages, and the working conditions. That’s something we can help you with!

Get Your Steel Strapping at Melbourne Packaging Supplies

For businesses in Australia that are looking for reliable and high-quality packaging solutions, at Melbourne Packaging Supplies, we’re here to help you. We offer a comprehensive range of packaging materials, including various types and grades of steel strapping, along with all the necessary tools and accessories for effective and safe strapping. Our experience, expertise and extensive product range means we can help you find just what you need.

Get in touch with us today to discuss your packaging needs.

Recent Comments