You’ve probably heard how a pallet wrapping machine can save you thousands per year on wrapping. They certainly can if you’re a high volume user who has been hand wrapping. But to save a significant amount you need to buy a Powered prestretch wrapping machine.

Click here for more information on our full range of pallet wrapping machines

How do they work?

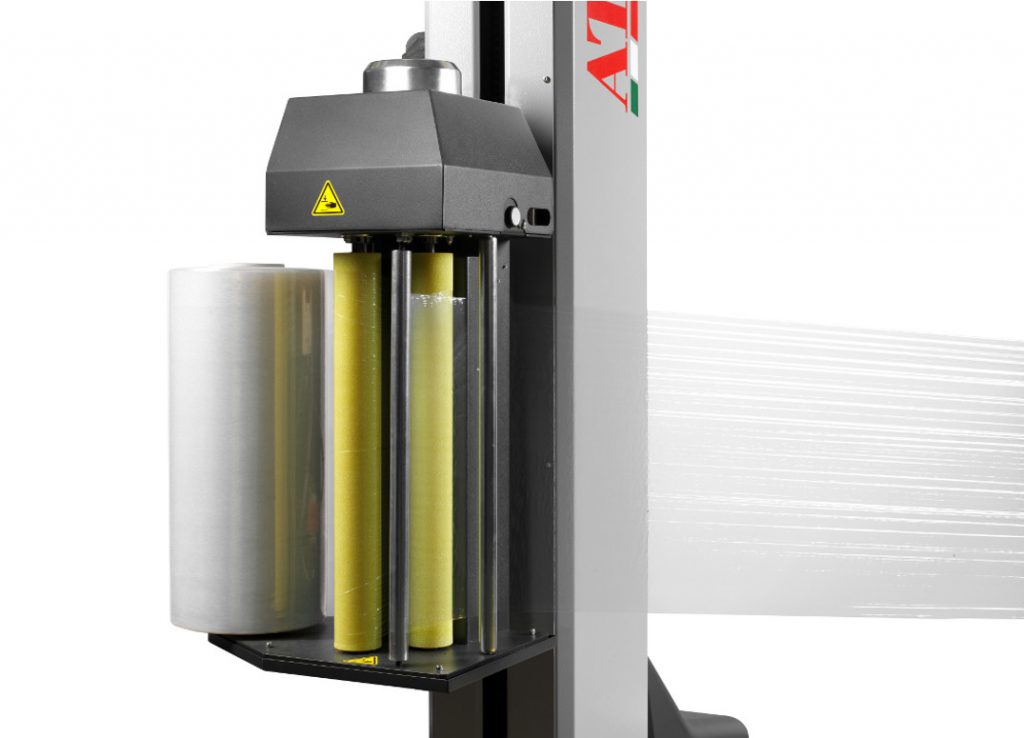

A powered prestretch machine(PPS) works by stretching the wrap further than a regular machine or a hand user can, it does this by stretching the wrapping in its power rollers and applying it thinly.

a PPS machine will stretch 1M of wrap out to 3m.

Example

We’ve done a test recently for a higher volume user.

These are 2 wraps priced relatively the same.

| Code | Description | Roll Price | KG price |

| HAC20A | 500MM X 20UM X 3.7KG NETT CLEAR CAST HAND STRETCHWRAP-AUS | $14.17 | $3.82 |

| HAE20 | 500MM X 20UM X 14KG NETT CLEAR CAST MACH. WRAP – IMPORTED 300% YIELD. | $49.90 | $3.56 |

We tested on 2 machines and by hand.

All wrapped:

Wrapped 3 times at the bottom, 3 times at the top, wrapped up and down.

Machine Settings:

Electromagnetic brake machine Set to 65% Film Braking.

3 bottom wraps, 3 top wraps.

PPS Machine Settings:

Equipped with 220% PPS ratio (3.2x)

3 Bottom wraps, 3 top wraps.

| Type | Stretchwrap used | 1 pallet | 100 pallets | 1000 pallets | 10,000 Pallets |

| Hand | 443g | $1.69 | $169.00 | $1,690.00 | $16,900.00 |

| Electromagnetic | 434g | $1.54 | $154.00 | $1,540.00 | $15,400.00 |

| PPS | 175g | $0.62 | $62.00 | $620.00 | $6,200.00 |

Now mind you by hand i wrapped this pretty well and put a lot of effort in, a hand user might not always be stretching wrap this much.

But you can see here there are significant savings to be had. We cut the film off each pallet and weighed them.

From left to right, Hand wrap, electromagnetic Brake, and Powered pre stretch.

The other advantages of a PPS stretchwrap machine are:

More environmentally friendly.

Not only do you save a significant amount of cost on wrapping, but you save a significant amount of wrap ending up in landfill. If this is a concern for you please enquire about our new Biodegradable stretchwrap range.

Better load retention of goods

Not only does a PPS machine save you a lot on stretchwrap costs, it secures the goods better than by hand or a typical machine. as the wrap is stretched from 1 meter to 3 meter. the wrap however wants to go back down to 1m, so it tries to shrink back down. securing your goods better.

Better for light goods

As a typically machine will use “force to load” to stretch the wrap. a PPS machine uses a lode cell or dancer roller. the wrap is already stretched by the motors and dispensed out, so there is very little force applied to goods. we have customers wrapping extremely light loads with just a PPS machine and no top pressor plate.

FAQ:

I’m worried that the machine will apply too thinly and it might tear.

this isn’t really an issue, PPS machines apply the film with a highly sensitive dancer roller or lode cell. there is hardly any force between the machine and the goods unlike a hand user or standard machine. so tearing isn’t really an issue.

These pallets are about the sharpest thing we could find in our warehouse, We staggered them for more sharper edges. look at how tight it applies the wrap.

this is 25um film applying at about 8um.

Do i need to run different film?

You will need to run a machine film, and you will need to run one of our PPS machine films capable of +200% stretch.

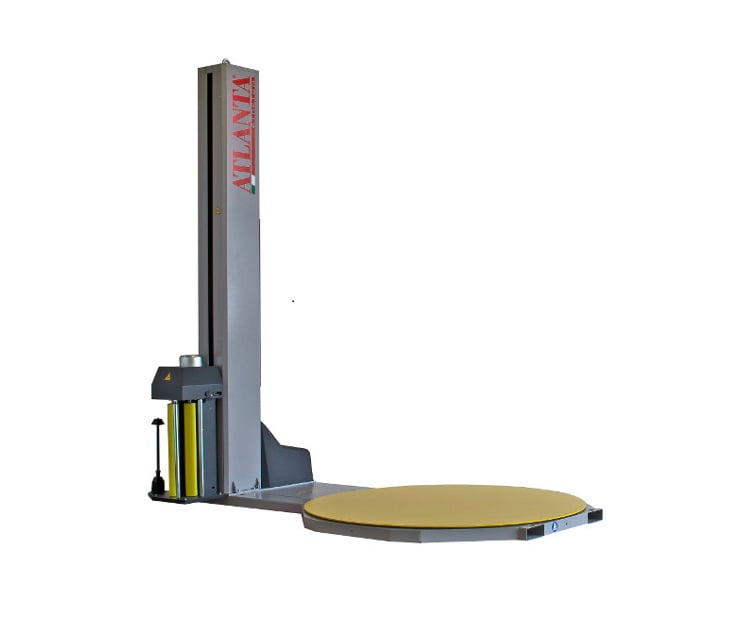

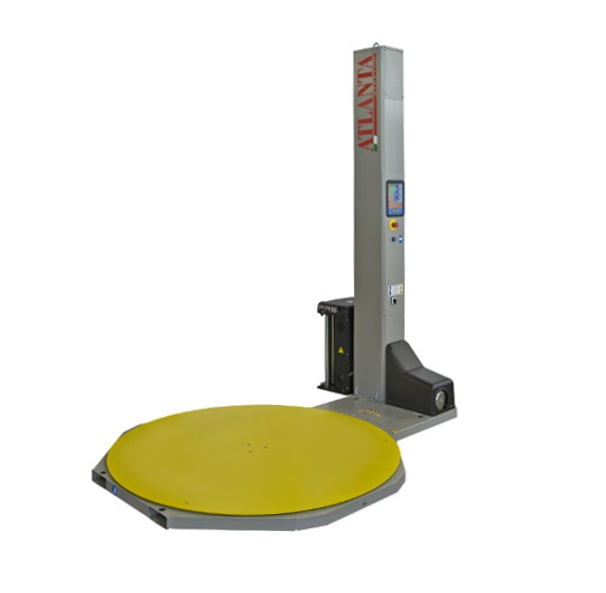

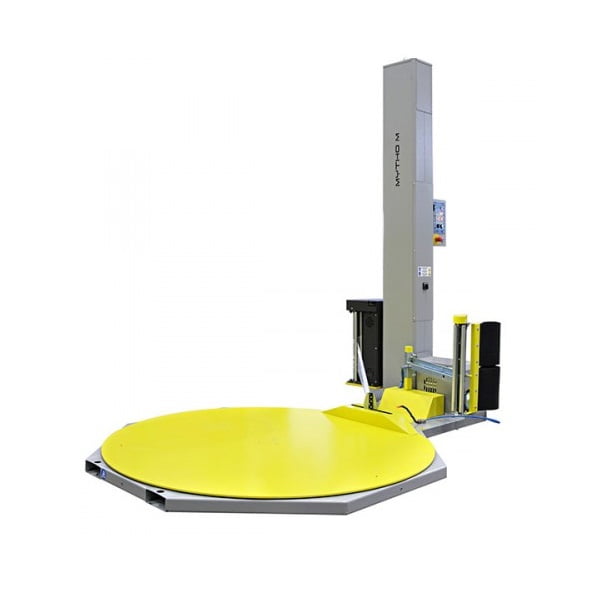

What PPS machines do you offer?

We have several models available.

Videos:

Watch the Mytho auto PRS/ PPS here:

Mytho PRS/PPS here

Synthex OPS /PPS here

Synthex – 2000KG Capacity – Pre stretch – Pallet Wrapping Machine – Version XF4010

Recent Comments