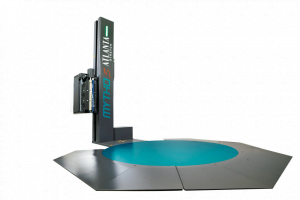

Automatic Pallet Wrapping Machine -Mytho Auto – Version XF6013

Automatic Pallet Wrapping Machine -Mytho Auto – Version XF6013

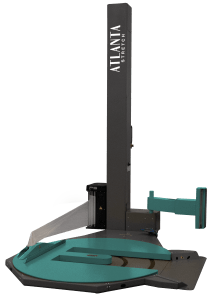

The Atlanta Stretch Mytho Automatic pallet wrapping machine is our top of the range pallet wrapping machine. Built for users in high production warehouses where operators want to drop a pallet on the machine and drive away. With just the press of a button on the remote the Mytho auto pallet wrapper will begin wrapping. When you return the pallet will be ready to remove from the turntable, with the film end attached to the pallet.

2 Remotes are includes with the Mytho Auto.

Melbpack is the Importer in Victoria for Italian Atlanta stretch turntable machines, buy direct from us and save thousands on your purchase price and ongoing spare parts.

Video

New design, changes to covering and protection plates.

Advantages:

- Remote control

- Italian Made by Atlanta Stretch

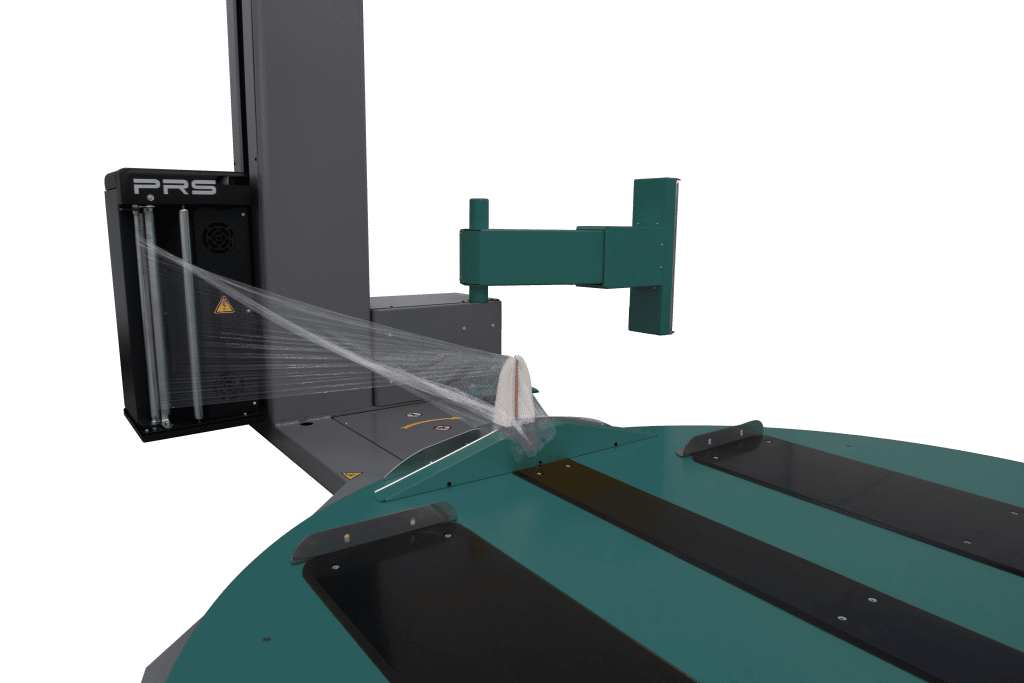

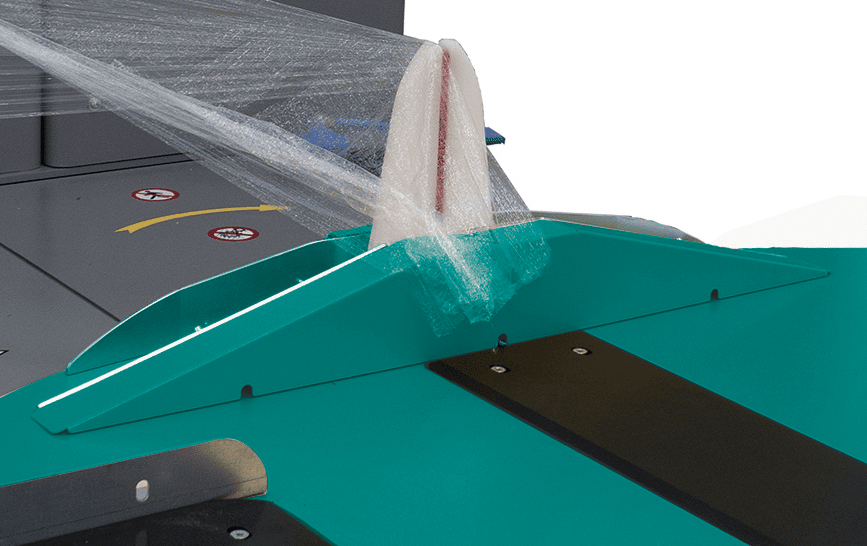

- High Yield PRS carriage 1m of wrap makes 3.5m

- Advanced Interface

- 240v, 6 Bar plug and Play

PARAMETERS ADJUSTABLE FROM CONTROL PANEL:

- Bottom pallet wrapping rounds from 1 to 10

- Top pallet wrapping rounds from 1 to 10

- Rotation speed adjustable from 5 to 12 rpm

- Spool carriage speed upwards and downwards independently adjustable

- Spool carriage speed upwards speed from 1,3 up to 5,4 m/min

- Spool carriage speed downwards speed from 1,3 up to 5,4 m/min

- All function parameters settable on display

- Photocell sensing delay

- All function parameters settable on display

- Weight of film used (Option on PRS – PS)

- Key block

BASIC CYCLES SELECTABLE FROM CONTROL PANEL:

- Double cycle (Upwards / Downwards)

- Single cycle (Only upwards or only downwards)

- Top sheet cycle

- Wrapping cycle with altimeter (Photocell Off)

- Wrapping cycle with start and stop height pre-programmed

- Wrapping cycle with reinforcement and settable number of wraps

- Wrapping cycle with step rising of spool carriage

- Manual wrapping programme

- Push-buttons for manual functions

TECHNICAL FEATURES:

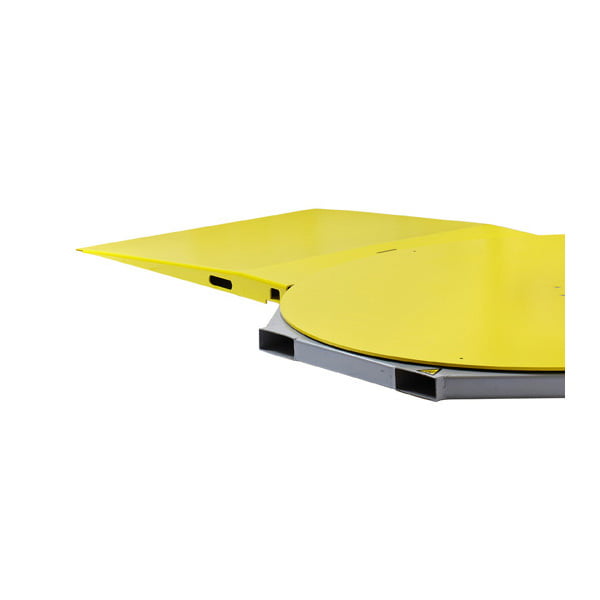

- Turntable Ø 1800 mm

- Max. load weight: 2000 Kg

- Wrapping height (Pallet included) 2500 mm

- Base-frame turntable height 75mm

- Load height sensing photocell and altimeter

- Acceleration / Deceleration ramps controlled by frequency changer

- Spool carriage upwards/downwards speeds controlled by frequency changer

- Safety carriage foot protection

- Beeper at cycle start and phase stopping at cycle end

- Emergency mushroom & reset push-button according to latest CE Norms

- Safe enclosed mast design with chain drive.

POWER REQUIREMENTS

| Total installed power | 1,00 KW (with carriage PRS / PS) |

| Standard input voltage | 230V mono-phase – 50/60 Hhz 10AMP |

| Outlet | AU standard plug |

| Pneumatic Pressure | 6 bar |

FILM CARRIAGE OPTIONS:

The Mytho auto, XF-6013 version is equipped with a PRS film carriage. Capable of stretching wrap from 1m to 3.5m

WARRANTY INFO

Please visit our warranty page for current warranty info.

UPGRADE OPTIONS

The Mytho is a highly customisable wrapping platform.

STOCK OPTIONS

These options are Bolt on and can be added by MPS, other options requiring changes to the mast or frame etc, will be custom build orders.

- Height sensing photocell for black or shining products (Stock)

- 150% or 200% Gear-set for pre-stretch

ALL UPGRADE OPTIONS.

- Height sensing photocell for black or shining products

- Additional adapter Kit for coreless stretch film

- Additional adapter Kit for stretch film core 50 mm inside diameter

- Extra cost – Spool Carriage for Net wrapping (FM & FE Carriage)

- Automatic roping system for wrapping reinforcement

- Electric driven pressure plate (Round or Rectangular) with automatic operation for loads from 600 mm up to an unlimited stroke

- Kit for wrapping doors or windows

- Pallets weighting system integrated in the machine

- Printer for integrated weighting system

- Wireless scale data transmission

- Stretch film weight consumption check

- Pallet maintenance & control / production counter Incl. Stretch-film usage

- Remote control (START / STOP)

- Remote control with selection of 6 programs

- Extra transmitter remote control

OPTIONAL MACHINE BASEFRAME & MEANS OF LOADING THE PALLETS:

- Base plate Ø 2200 mm, Max. load dimensions 1550 x 1550 mm

- Base plate Ø 2400 mm, Max. load dimensions 1675 x 1675 mm

- Max. load weight: 3000 KG (Not for TP machines)

- Longer Basement (Not for TP machines)

- Base plate TP Ø 1650 mm with Trans-pallet turntable

- Ramp for plate Ø 1800

- Ramp for plate Ø 2200

- Reinforced Ramp Ø 1500 up to Ø 2400 mm

- Extended Ramp Ø 1500 up to Ø 2400 mm

The grounding kit or “pit frame” is used to put the machine into the ground, embedding it into the concrete.

- Grounding KIT for plate Ø 1800 mm

- Grounding KIT for plate Ø 2200 mm /

- Idle conveyor on turntable with automatic rollers braking device

- Mast for wrapping height 2200 mm (Reduces price)

- Mast for wrapping height 2700 mm

- Mast for wrapping height 3000 mm

- Mast for wrapping height 3300 mm

- Mast for wrapping height 3700 mm

- Kit for wrapping doors or windows

- Second carriage with bubble film or foam

- Pallets weighting system (Scales) integrated in the machine (Not available for low profile turntable)

- Pallets weighting system (Scales) integrated in the machine TP version

- Printer for integrated weighting system

- Wireless scale data transmission

QUESTIONS

Where and who by is this machine built?

Our pallet wrapping machines are built in Italy by Atlanta Stretch, Melbpack is the direct importer for Atlanta stretch and seller of machines to end users. allowing customers to have an Atlanta stretch machine at the best price and spare parts at the best possible rate.

Do i need any special power requirements to run this Machine?

No this will fit into any standard 230/240v AU plug. 10Amp Plug. you will also need a 6 bar of pneumatic pressure to run the Mytho auto.

Legacy Video:

Please note, features old arm design, see our video up the top for the new design.