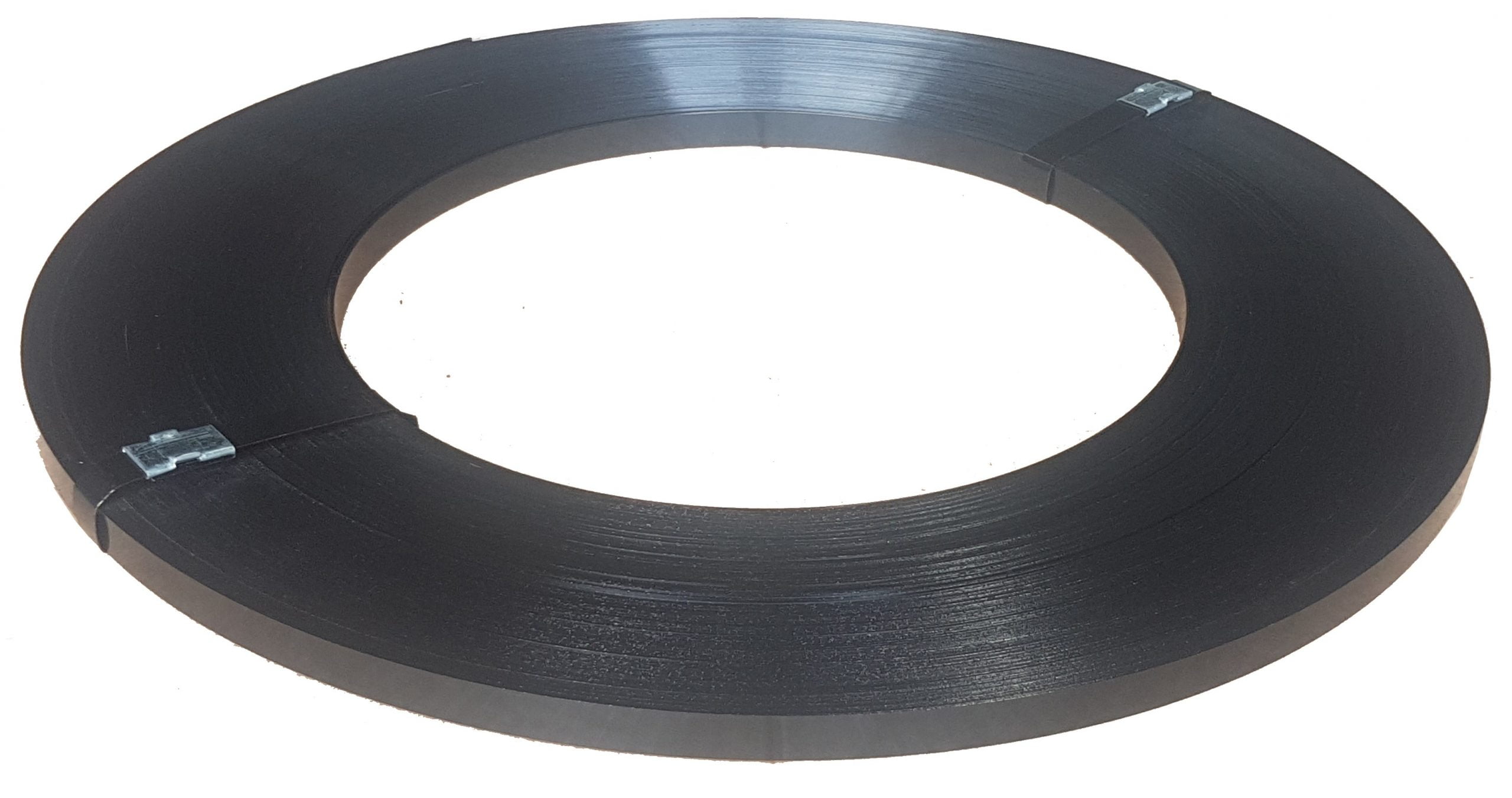

APEX 19056 BLACK RIBBON STEEL STRAPPING

APEX 19056 BLACK RIBBON STEEL STRAPPING

Product information:

APEX 19056 BLACK RIBBON STEEL STRAPPING (KG)

We provide the highest quality steel strapping. We supply Australian made steel strapping using BlueScope steel. All our steel is painted, waxed and thoroughly deburred to remove sharp edges.

Advantages

- Australian Made

- Thoroughly deburred for sharp edges

- Smooth Painted and Waxed Finished

Specification:

APEX 19056 BLACK RIBBON STEEL STRAPPING (KG)

Technical data:

| Brand | BlueScope |

| Avg. Breaking Strain | 787KG |

| Meters Per KG | 12 |

| Inner Dimensions (MM) | 170MM |

| Outer Dimensions (MM) | 420MM |

| Roll Weight: | 16KG |

| Pallet Qty | 36 |

| Meters per Roll | 192M |

Availability and delivery

AAK3A 19MM Black Ribbon Steel Strapping is in stock and available for immediate delivery.

Melbourne Metro: 1-2 Business days

Regional Victoria: 2-3 Business days

Sydney, Brisbane, Adelaide Metro: 2-3 Business days

All other locations: TBA

Dispatch lead time is from when funds are received, orders processed after 2pm may not be despatched until the next day to deliveries outside of Melbourne metro.

FAQ

What is the breaking strain of this Strapping?

AAK3A Average breaking strain is 787KG

Do you carry steel strapping In stock?

Yes we do, tonnes in fact, we’re one of the largest steel strapping providers in Australia.

Is steel strapping or plastic strapping better?

It really depends on the application and type of plastic strapping compared steel has the advantage of a low elongation so it keeps good tight on logner trips and is easy to bundle around round and small goods. its highly used in the steel industry for this reason.

Do you sell steel by the KG or roll?

We sell ribbon steel strapping in multiple of 3 coils, by the KG.

How many meters will I get per roll?

In our 19056 ribbon, in its approx 16kg roll you get approximately 192m.

Whats the best way to apply steel strapping?

One of the fastest way is with our MUL20 strapping tool it tensions, seals and cuts. saving siginficant time and costs of seals per strap. The MUL20 separates itself from the rest of the sealless market with its easy to adjust cutting depth and feedwheel height, saving people hundreds of dollars per year in maintenance.