Rotating Arm stretch wrapper – Lybra Auto

Rotating Arm stretch wrapper – Lybra Auto

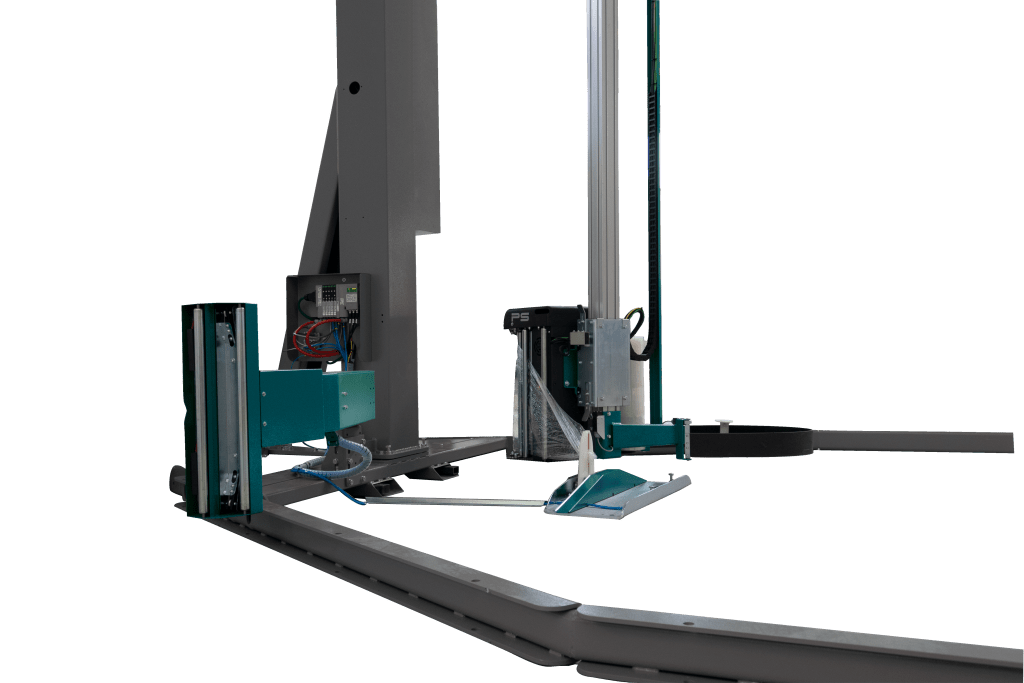

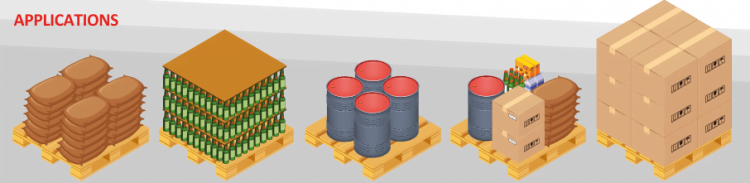

The Lybra Auto rotating arm stretch wrapper is a heavy duty rotating arm stretch wrapper, build in Italy by Atlanta stretch

Advantage

- Easy to use with pallet jacks or Tuggers etc.

- Great for unstable goods

- great for heavy goods

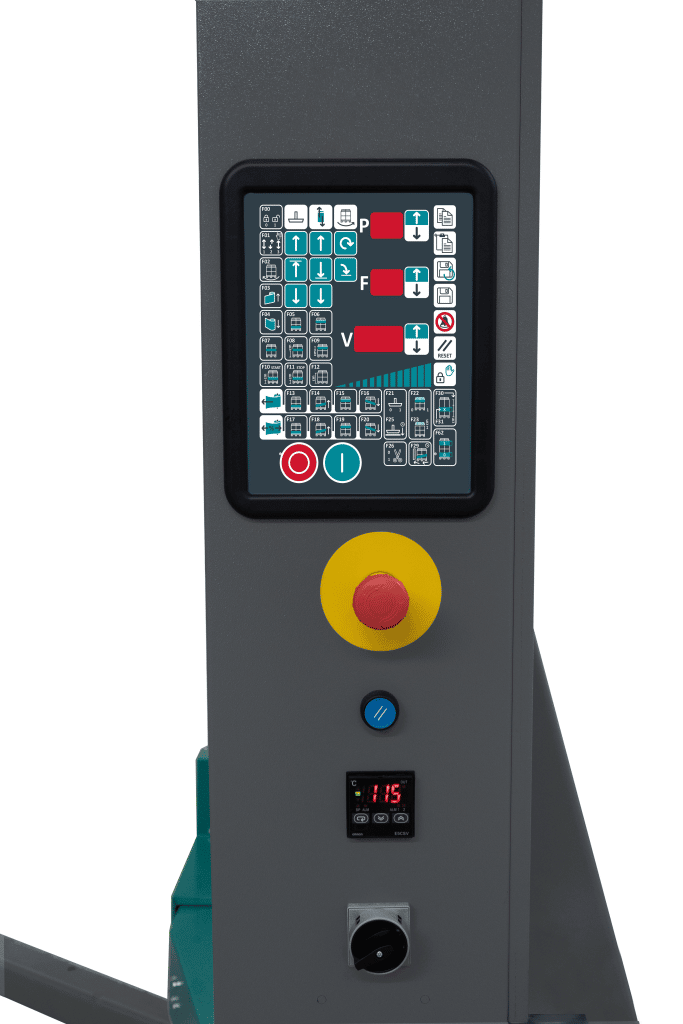

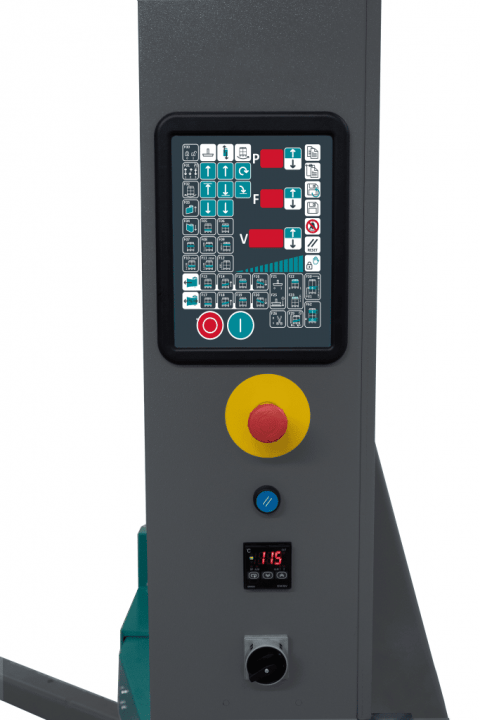

Easy to use interface

The lybra Easys interface is easy to use and proven .

Want to buy the Lybra Easy rotating arm stretch wrapper?

Please call use to buy or for a quote on the Lybra Easy rotating arm stretch wrapper.

Feature Summery

PARAMETERS ADJUSTABLE FROM CONTROL PANEL:

- All function parameters settable on display

- F00 – Key block

- F02 – Rotation speed adjustable from 5 to 12 rpm

- Spool carriage speed upwards and downwards independently adjustable

- F03 – Spool carriage speed upwards speed from 1,3 up to 5,4 m/min

- F04 – Spool carriage speed downwards speed from 1,3 up to 5,4 m/min

- F05 – Bottom pallet wrapping rounds from 1 to 10

- F06 – Top pallet wrapping rounds from 1 to 10

- F09 – Photocell sensing delay

- F13 – F16 – Set Film tension at four steps during the wrapping programm

- F17 – F20 – With PS Carriage, set Film pre-stretch at four steps during the wrapping programm

- F62 – Comfort height for easy coil change

- Weight of film used (Optional

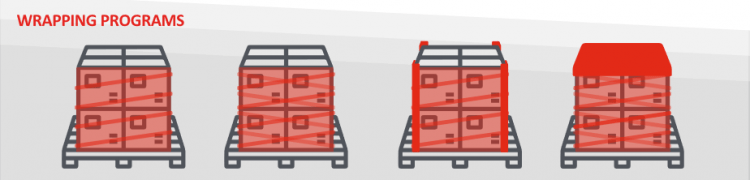

BASIC CYCLES SELECTABLE FROM CONTROL PANEL:

- 99 Wrapping programs created by the operator

- F01 – 1 – Double cycle (Upwards/Downwards)

- F01 – 3 – Push-buttons for manual functions

- F12 – Wrapping cycle with altimeter (Photocell Off)

- F22 / F23 – Top sheet cycle

- F30 – F31 – Step Wrapping cycle with reinforcement and settable number of wraps

- Softstart cycle to reduce film tear on sharp pallet angles

- Wrapping cycle with manual or motorized roping system (If optional installed)

- Reinforcement cycle by means of push-buttons

TECHNICAL FEATURES:

- diameter Ø 2.075 mm

- Max. load dimensions 1.200 x 1.200 mm

- Wrapping height (Pallet included): 2.200 mm

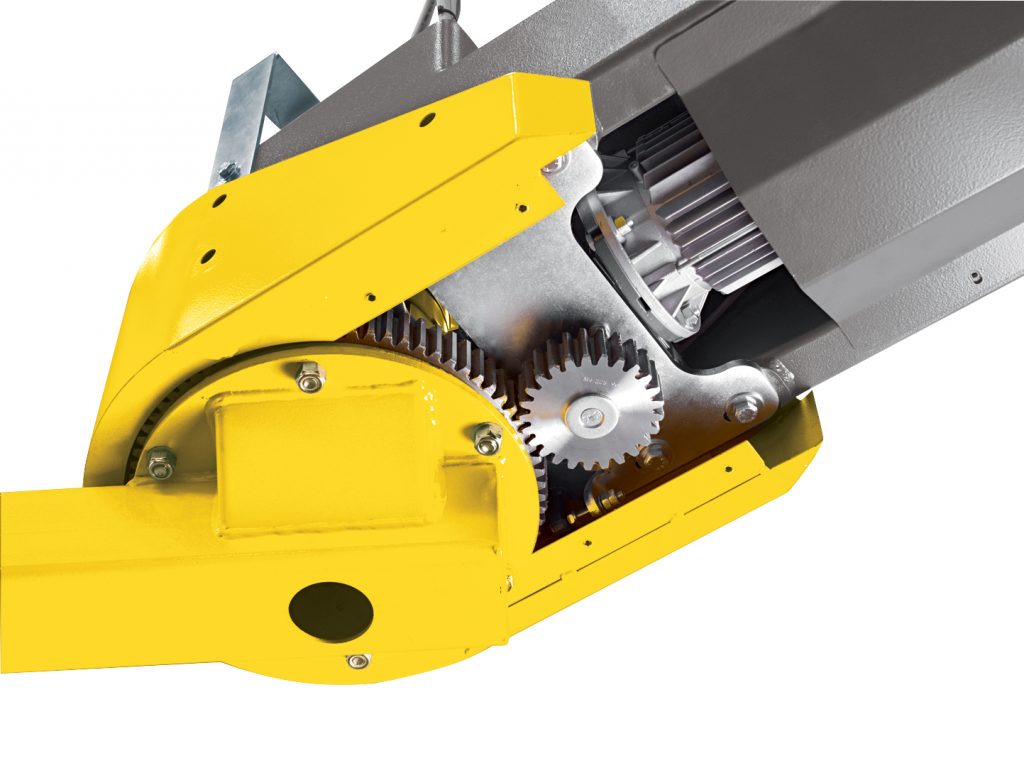

- Rotating arm on heavy duty bearing transport

- Load height sensing photocell

- Acceleration / Deceleration ramps controlled by frequency changer

- Spool carriage upwards/downwards speeds controlled by frequency changer

- Beeper at cycle start and phase stopping at cycle end

- Emergency mushroom button according to CE Norms

- Adjustable change coil, carriage service height

- Safety bumper protection against collision

- Mechanical button to re-arm the machine according CE Normatives Ø 22mm

POWER REQUIREMENTS

| Total installed power | 1.5 KW (with carriage PRS / PS) |

| Standard input voltage | 230V mono-phase – 50/60 Hhz 10AMP |

| Outlet | AU standard plug |

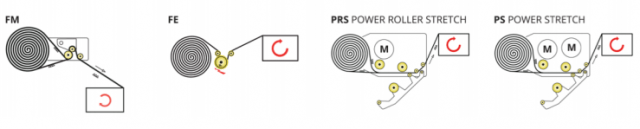

FILM CARRIAGE

Options

FE – Electromagnetic Brake

Heavy Duty brake capable of stretching film 0-100% (1x-2x Yield)

PRS Power roller stretch

Single motor prestretch, straps wrap from 150%-250%, preset to 200%

PS Power Stretch

Twin motor variable prestretch 150%-350% Prestretch

WARRANTY INFO

- Please visit our warranty page for current warranty info

MELBPACK DISCRIPTION

ATLANTA LYBRA EASY

LAYOUT

THE ADVANTAGE OF ATLANTA

Atlanta stretch are on of the largest machine builders in the world, trusted for the high quality machine design and robustness. Buying an Atlanta machine through Melbpack you have the backup from Melbpack and Atlanta Stretch.

MODULAR DESIGN

Atlanta stretch wrapping machines are of modular design, they all use the same parts where they can, increasing spare parts availability.

USE OF COMMERCIAL COMPONENTS AND INVERTERS

Atlanta Stretch pallet wrapping machines use off the shelf components from major parts providers such as Lenze, Omron, Motovario and micro-detectors. Increasing the quality of the parts and availability of them. Atlanta uses very few custom parts or boards, increasing the life expectancy of the machine due to parts availability and interchangeability of the parts.

QUESTIONS

Where and who by is this Automatic pallet wrapper built?

The Lybra Easy is built in Italy by Atlanta Stretch, Watch a video below of their build process for turntable pallet wrappers.

Do i need any special power requirements to run this pallet wrapping machine?

No this will fit into any standard 230v AU plug. 10Amp Plug.

Can i run this Machine in Manual mode as i have irregular pallets?

Yes you can, the Lybra easy has a manual mode of operation where you can manually turn the turntable by the interface and control the carriage height manually through the interface.

UPGRADE OPTIONS

STOCK OPTIONS

These options are Bolt on and can be added by MPS, other options requiring changes to the mast or frame etc, will be custom build orders.

- Height sensing photocell for black or shining products (Stock)

- Sonic sensor for items such as wrapping chairs or hollow goods. where infrared or photo logic isn’t suitable.