Synthesi – 2000KG Capacity – Friction Brake – Pallet Wrapping Machine – Version XF3110

Synthesi – 2000KG Capacity – Friction Brake – Pallet Wrapping Machine – Version XF3110

The Synthesi XF3110 pallet wrapping machine is a low maintenance Italian Made Pallet wrapping Machine, built by Atlanta Stretch SPa, and distributed by Melbpack.

The Atlanta Stretch Synthesi XF3110 pallet wrapper is an economical and easy to use wrapping machine, with many features for wrapping.

This pallet wrapper comes with a height detection photocell for semi automatic wrapping of pallets. With a 2000kg capacity and wrapping height of up to 2500mm, the XF3110 pallet wrapper is a versatile machine suitable for loads of industries and uses.

Want to know if the Synthesi XF3110 pallet wrapping machine is right for your needs? Talk to us today at MelbPack.

Video

(Video shows XF-3111, electromagnetic brake version)

Recent Installs

Pallet wrapping machine for Box manufacturer

Feature Summery.

- Automatic 1 Button Push start

- Heavy Duty electromagnetic Brake. 0-100% Stretch.

- Automatic pallet Height detection

- 3 Fully adjustable Auto programs, Plus manual mode of operation.

- 10 adjustable parameters, see below for complete list.

- 2000kg Capacity

- 2500mm Wrapping height

- 1650mm diameter turntable for Australian and export pallets.

- Made in Italy by Atlanta Stretch.

- Built with German Lenze electrical components.

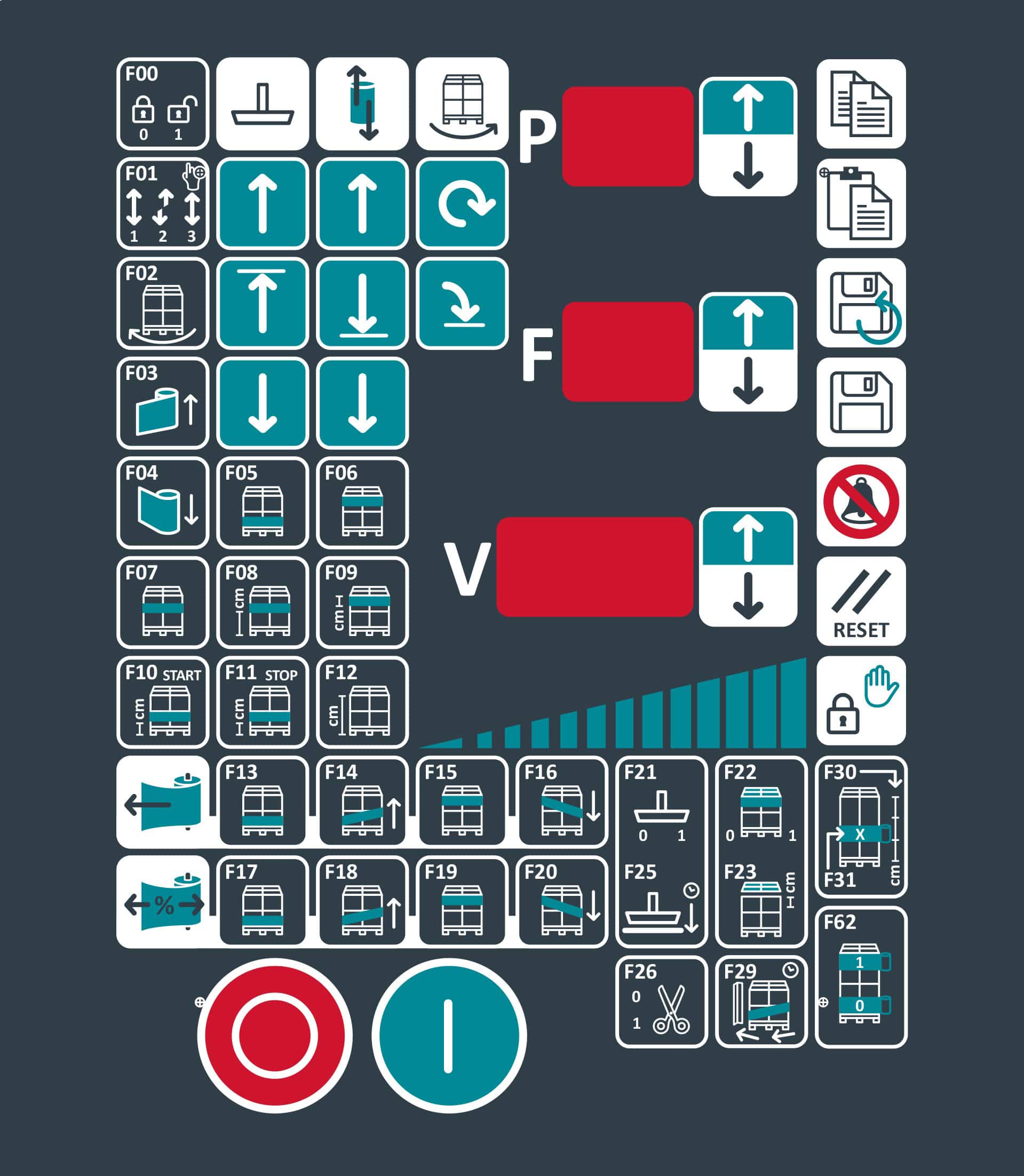

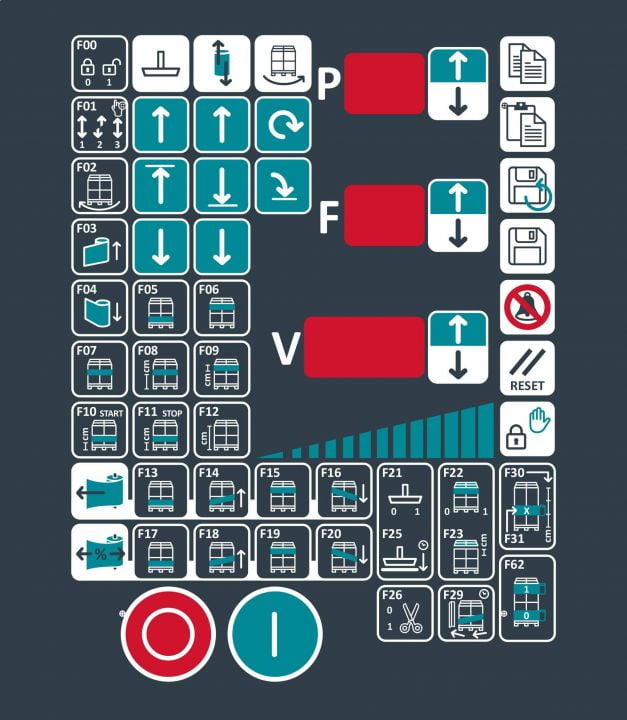

PARAMETERS ADJUSTABLE FROM CONTROL PANEL:

- Bottom pallet wrapping rounds from 1 to 10

- Top pallet wrapping rounds from 1 to 10 Rotation speed adjustable from 5 to 12 rpm

- Spool carriage speed upwards and downwards independently adjustable

- Spool carriage speed upwards speed from 1,3 up to 5,4 m/min

- Spool carriage speed downwards speed from 1,3 up to 5,4 m/min

- All function parameters settable on display

- Photocell sensing delay

BASIC CYCLES SELECTABLE FROM CONTROL PANEL:

- Double cycle (Upwards / Downwards)

- Single cycle (Only upwards or only downwards)

- Top sheet cycle

- Wrapping cycle with altimeter (Photocell Off)

- Wrapping cycle with pre-set starting and stopping height

- 3 + 1 selectable wrapping programs

- Wrapping cycle with manual drive by push-buttons of the carriage Up / Down

- Push-buttons for manual function

TECHNICAL FEATURES:

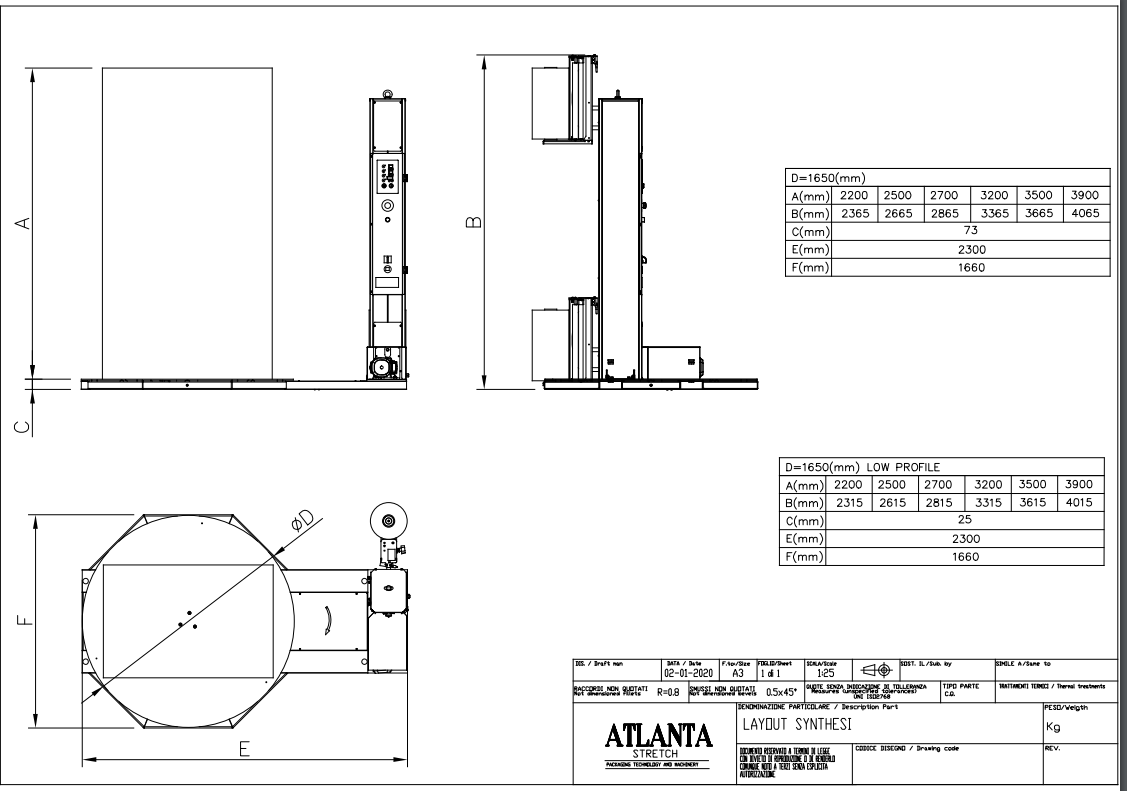

- Turntable Ø 1650 mm

- Max. load weight: 2000 Kg

- Wrapping height (Pallet included) 2500 mm

- Base-frame turntable height 75mm

- Load height sensing photocell and altimeter (without photocell with pre-set height)

- Acceleration / Deceleration ramps controlled by frequency changer

- Spool carriage upwards/downwards speeds controlled by frequency changer

- Safety carriage foot protection

- Beeper at cycle start and phase stopping at cycle end

- Emergency mushroom & reset push-button according to latest CE Norms

- Adjustable change coil, carriage service height

- Safe enclosed mast design with chain drive.

POWER REQUIREMENTS

| Total installed power | 1.75KW Inc. electromagnetic Brake |

| Standard input voltage | 230V mono-phase – 50/60 Hhz 10AMP |

| Outlet | AU standard 10 amp plug |

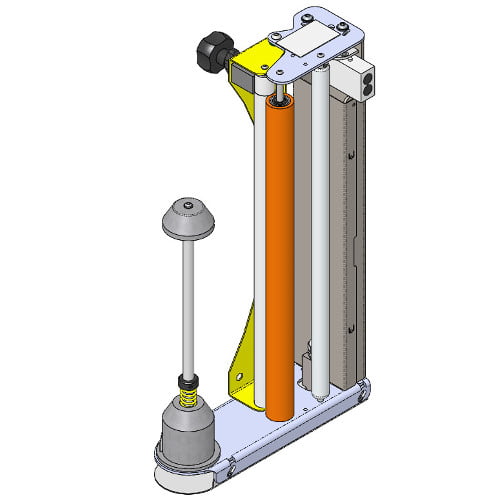

FILM CARRIAGE FEATURES:

The Synthesi as standard has a friction mechanical Brake, the Synthesi is capable of been upgraded to an Electromagnetic brake or is available on our other Stock Synthesi the XF3111.

- Brake system by means of tension roller

- Manually adjustable from carriage

- Film reel specs Max. outside diameter Ø 250 mm – Height = 500 mm

- Core Ø76mm

- Mounted on opposite side to the control panel to keep users clear of it during operation.

WARRANTY INFO

- Please visit our warranty page for current warranty info.

DELIVERY DETAILS

- The Synthesi is a stock wrapping machine at Melbpack. We can have a machine ready to go in just acouple of days from your order.

(Please confirm current stock availability at quotation time)

LAYOUT

Info on the manufacturer

We believe its important for our customers to know the manufacturers and origin of the products we sell. So not only do you have the backing of Melbourne Packaging, but you can always get in contact with the manufacturer too.

Our XF series of pallet wrapping machines is built by Atlanta Stretch in Italy. Atlanta Stretch are builders of premium wrapping machines. For more info on Atlanta stretch, Visit their website: Atlanta Stretch

Also checkout our youtube video below of the machines been Made in Italy and crated for export.

QUESTIONS

Do i need any special power requirements to run this Machine?

No this will fit into any standard 230/240v AU plug. 10Amp Plug.

Do i need any special power requirements to run this Machine?

No this will fit into any standard 230/240v AU plug. 10Amp Plug.

Can i run this Machine in Manual mode as i have irregular pallets?

Yes you can, the Synthesi has a manual mode of operation where you can manually turn the turntable by the interface and control the carriage height manually through the interface.

What is an electromagnetic brake?

And electromagnetic brake is very simialr to a standard mechanical brake, however, instead of relying upon friction a powerful electromagnet slows the speed of the rollers and applies film tension. They great for uses needing a long life durable machine. Even at super high volume users electromagnetic brakes last 2-4 years before needing any replacement parts.

UPGRADE OPTIONS

The Synthesi is a highly customisable wrapping platform.

STOCK OPTIONS

These options are Bolt on and can be added by MPS, other options requiring changes to the mast or frame etc, will be custom build orders.

- Height sensing photocell for black or shining products (Stock)

- A – Ramp for plate Ø 1500 / Ø 1650 mm (Stock at Melbpack)

ALL UPGRADE OPTIONS.

FILM CARRIAGE OPTIONS (Additional cost)

- Height sensing photocell for black or shining products (Stock)

- Additional adapter Kit for coreless stretch film (Custom order)

- Additional adapter Kit for stretch film core 50 mm inside diameter (Custom order)

- Spool Carriage for Net wrapping (FM & FE Carriage) (Custom order)

- Manual roping system for wrapping reinforcement (Custom order)

- Downgrade to Friction “FM” mechanical brake. (Reduces Price, Custom Order)

OPTIONAL MACHINE BASEFRAME & MEANS OF LOADING THE PALLETS:

- Base plate Ø 1500 mm, Max. load dimensions 1000 x 1200 mm (Reduces price)

- Base plate Ø 1800 mm, Max. load dimensions 1250 x 1250 mm

- Base plate Ø 2200 mm, Max. load dimensions 1550 x 1550 mm

- Base plate Ø 2400 mm, Max. load dimensions 1675 x 1675 mm

- Max. load weight: 3000 KG (Not for TP machines)

- Longer Basement (Not for TP machines)

- Base plate TP Ø 1650 mm with Trans-pallet turntable

- Ramp for plate Ø 1500 / Ø 1650 mm (Stock at Melbpack)

- Ramp for plate Ø 1800

- Ramp for plate Ø 2200

- Ramp for plate Ø 2400

- Reinforced Ramp Ø 1500 up to Ø 2400 mm

- Extended Ramp Ø 1500 up to Ø 2400 mm

*TP= Transpallet

The grounding kit or “pit frame” is used to put the machine into the ground, imbeding it into the concrete.

- Grounding KIT for plate Ø 1500 mm

- Grounding KIT for plate Ø 1650 mm

- Grounding KIT for plate Ø 1800 mm

- Grounding KIT for plate Ø 2200 mm / 2400mm

Option: Low profile turntable:

- Guides for wrapping supermarket trolleys

- Idle conveyor on turntable with automatic rollers braking device

- 12 CM lifting basement to allow pallet loading with electric lifter

- Mast for wrapping height 2500 mm

- Mast for wrapping height 2700 mm

- Mast for wrapping height 3000 mm

- Mast for wrapping height 3300 mm

- Mast for wrapping height 3700 mm

- Kit for wrapping doors or windows

- Second carriage with bubble film or foam

- Pallets weighting system integrated in the machine (Not available for low profile turntable)

- Pallets weighting system integrated in the machine TP version

- Printer for integrated weighting system

- Wireless scale data transmission